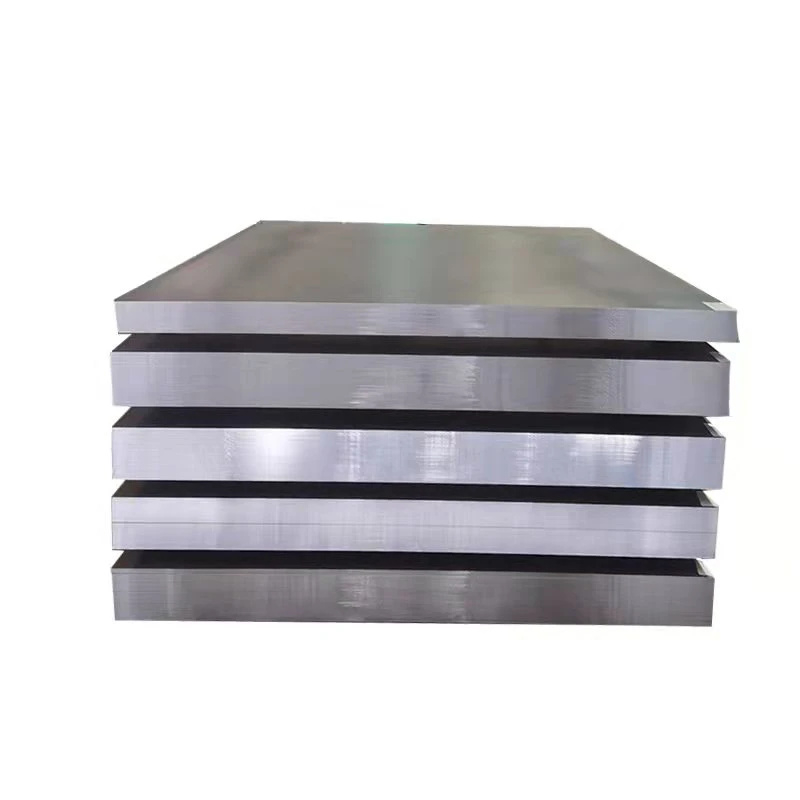

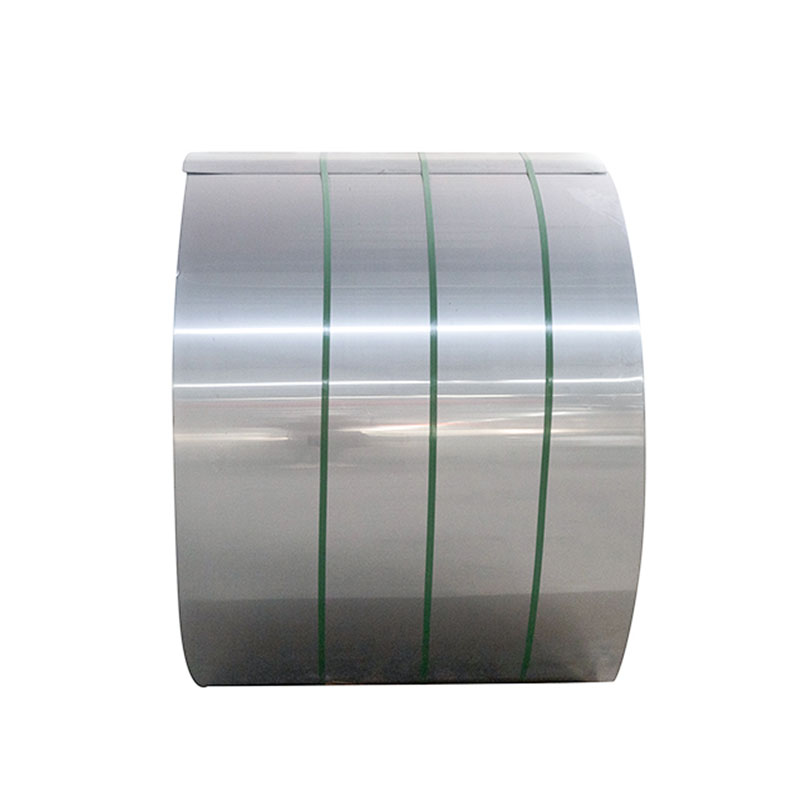

Silicon Steel

Product Parameters

| Standard | GB/T 2521-2008 |

| Grades | 50W800, 50W600, 50W470, 65W800 |

| 27Q120, 27Q110, 23Q100, 23Q90, 23Q80 | |

| Coating | organic coating |

| Semi organic coating | |

| inorganic coating | |

| Self-bonding coating | |

| Sizes | NGO 0.2-0.65 mm, Iron loss: 2.1--13.0w/kg;

GO 0.15-0.35 mm, Iron loss: 0.58--1.3 w/kg |

Product Characteristics

● Low hysteresis and eddy current losses due to high permeability, low coercivity and high electrical resistance of silicon steel.

● In order to meet the need of punching and cutting process when manufacturing electrical appliances, it is also required to have a certain degree of plasticity. In order to improve the magnetic susceptibility, reduce hysteresis loss, the lower the content of harmful impurities is required as good as possible, and requires a flat plate, good surface quality.

● The production process of hot rolled silicon steel has now been phased out in China, and cold rolled silicon steel is now produced and supplied.